Adapting a Tillotson HR series carb to you stock McCulloch manifold – by Rob Voska

Back in the 80’s a big class was “100 controlled stock”. The engines came with Tillotson HR181 & later HR191 carbs and also the popular Mikuni carb. There are lots of Tillotson carbs for sale on Ebay but they are usually snowmobile carbs and I do not know if the fuel curve is correct for your engine. These carbs are easily adapted to your stock McCulloch manifold and reed cage. I will assume that by looking at the pictures you will be able to figure this out and do this with a few hand tools in a little more than an hour of your time and end up with a more dependable carb than the stock McCulloch carb without the duckbill problems.

1. Stop and get some brake or fuel line at your local auto parts store. I used 1/4 inside diameter and 5/16 outside. You need this for some spacers to take up the slop between the 5/16″ hole in the carb and the 1/4″ stud. BEFORE cutting these off run a 1/4″ drill down the inside of the tube to get rid of the weld seam. Hacksaw off 2 pices 1/32″ shorter than the mounting flange of your carb. A tubing cutter does not work well as it crushed the tube and you have to go back and try to hold it to deburr it. Slide the spacer on the end of an old 1/4″ bolt to help you if you need to touch it to a grinder to clean or even it up.

2. Take the gasket for your HR carb and line it up on the back of your carb and make sure the pulse hole is lined up. Trim if needed.

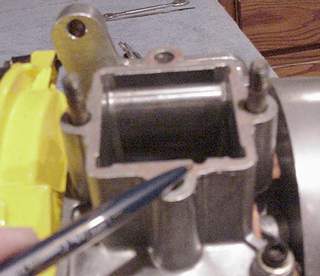

3. Slide the spacers you made on the 1/4″ mounting studs and set the gasket on top of the stock reed cage and mark where the hole should be. (Picture # 360)

4. Drill pulse hole 1/8″ diameter in the reed cage. Remove reed cage from engine before drilling so you do not get any chips down inside of your engine. You want it to run better when done not worse.

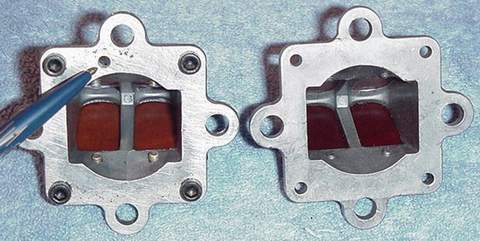

5. Check inside of manifold with the reed cage as there is a small amount of interference and you will need to put a small “U” shape clearance in the manifold to get a good clear pulse hole. A small round file or a die grinder works great. Keep the chips out of the engine or remove the manifold from the engine for this.

6. Tap the 4 holes in the corners of the stock reed cage 8-32 and install and locktite in some very short Allen bolts to block these holes. Buy extra, as you will drop 2-3 of them when you try to grind them to length. Make sure you do a good job and the head of the bolts stick OUT of the manifold.

7. Now all you really have to do is to bolt it together. And go have some fun.