Dart Chaparral Safety Update

Posted: Mon Jul 13, 2009 9:06 pm

I was at an event and saw a Dart Chaparral steering hoop come apart that ended up with a flip and a injured driver. Here is an idea to keep that from happening to you.

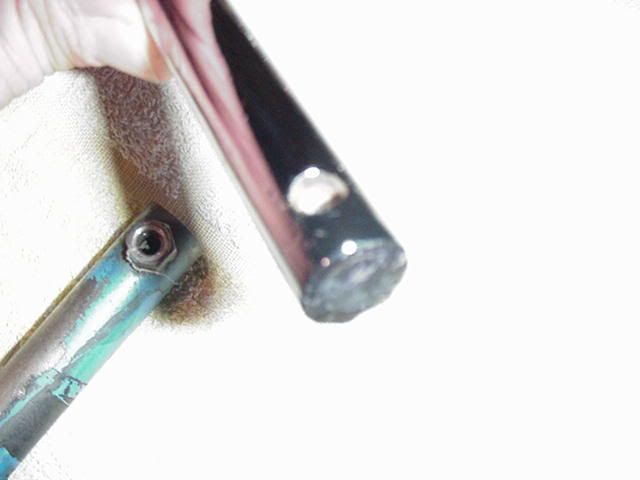

Standard Dart upper & lower steering hoop.

The way they are stock there is just a set screw or a short socket head allen bolt run in against a hollow tube. You don't tighten it much as the tube will crush. Also as we are bigger, older, heavier the hoop is usually in the highest position possible leaving very little room for any slipage so it can easly come out of the lower support.

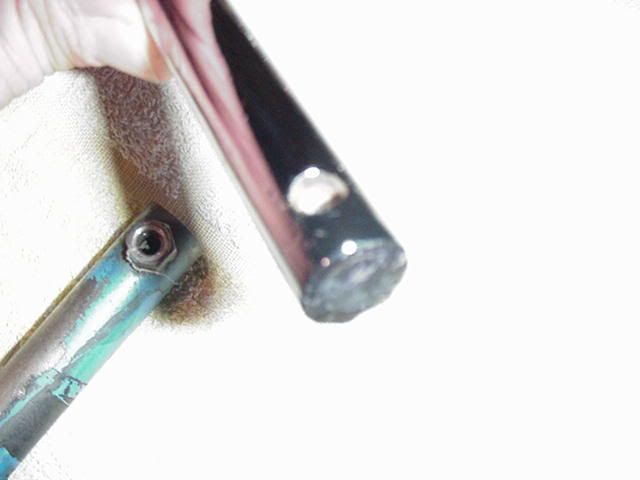

I took mine and slid a 1" long piece of cold rolled steel in. Tig welded it in before it got chromed. Then marked where the bolt would be and drilled a hole 1/2 way thru. That gives me a very good pocket for a short allen head bolt to seat against. In other applications I have also drilled a hole in 1 side of the tube and run a longer bolt so it went to the far side before clamping the hoop in place. That way it could not come out either. The head of the bolts should also be safety wired so they can't back out.

When done like this your kart is safer and no one can detect anything was ever done.

Remember this is for fun and we don't want to see anyone on their heads or tearing up any equipment.

Standard Dart upper & lower steering hoop.

The way they are stock there is just a set screw or a short socket head allen bolt run in against a hollow tube. You don't tighten it much as the tube will crush. Also as we are bigger, older, heavier the hoop is usually in the highest position possible leaving very little room for any slipage so it can easly come out of the lower support.

I took mine and slid a 1" long piece of cold rolled steel in. Tig welded it in before it got chromed. Then marked where the bolt would be and drilled a hole 1/2 way thru. That gives me a very good pocket for a short allen head bolt to seat against. In other applications I have also drilled a hole in 1 side of the tube and run a longer bolt so it went to the far side before clamping the hoop in place. That way it could not come out either. The head of the bolts should also be safety wired so they can't back out.

When done like this your kart is safer and no one can detect anything was ever done.

Remember this is for fun and we don't want to see anyone on their heads or tearing up any equipment.